Flotender Greywater Drip Irrigation Design

Residential Zone Sizing With GL Series Processors

Commercial Zone Sizing With GXL Processors

Choosing Between a GL Series Single Zone or a Multi-Zone Greywater System

Choose a GL Series Single Zone if:

- A single zone will cover the area to be watered

- The single zone size can be 120 GPH, 360 GPH, or 600 GPH depending on the pump selected

Choose a GL Series Multi-Zone if:

- Different areas of the landscape have selective water requirements

- The greywater landscape area requires more than the 600 GPH available with a Single Zone Greywater System

Note: A drip irrigation zone controller as well as a pump start relay is required with the Multi-Zone

A single drip tube run can have .4 GPH, or .6 GPH or .9 GPH drip emitters.

Maintaining a Constant Mosture Balance

A drip zone should water every day or every other day to establish and maintain a consistent moisture balance in the soil. A consistent moisture level allows the greywater to radiate laterally and vertically upward and downward as far as possible encouraging deep root growth.

Running a zone on a daily basis establishes large, wetted areas below the surface.

- Roots are allowed to reach deep into the soil

- Water reaches out to its maximum radius

- Maintains optimal water molecule movement with a consistent moist environment.

Ideally a greywater zone should run if not every day or at least every other day. If you allow the soil to go through dry/wet cycles, the area nearest the emitter will be the area where most of the roots will congregate. It will also make it harder for the water molecules to reach outward as far as possible. Daily or every-other-day irrigation allows the area immediately around the emitter to be at or above field capacity. When the soil is in this 'super-saturated' state, roots will grow within the entire wetted area and not just congregate at the emitter. When a zone operates on a daily basis or on a every-other day basis, you are simply maintaining a consistent and balanced level of moisture in the soil allowing the plants to thrive without having to 'search' for water.

Repeated Greywater Zone Dosing Promotes Deep Root Growth

Flotender's repeated slow dosing of greywater throughout the day maintains the best soil moisture absorption for deep root growth. Slow release buried dripline also eliminates the concern of greywater run-off from dry soil conditions.

Both Flotender Greywater Single Zone and Multi-Zone systems provide immediate disbursement of grey water to landscape planted areas as received from any indoor greywater source.

A Flotender Single Zone greywater system does not require a controller, electric zone valves or controller programing.

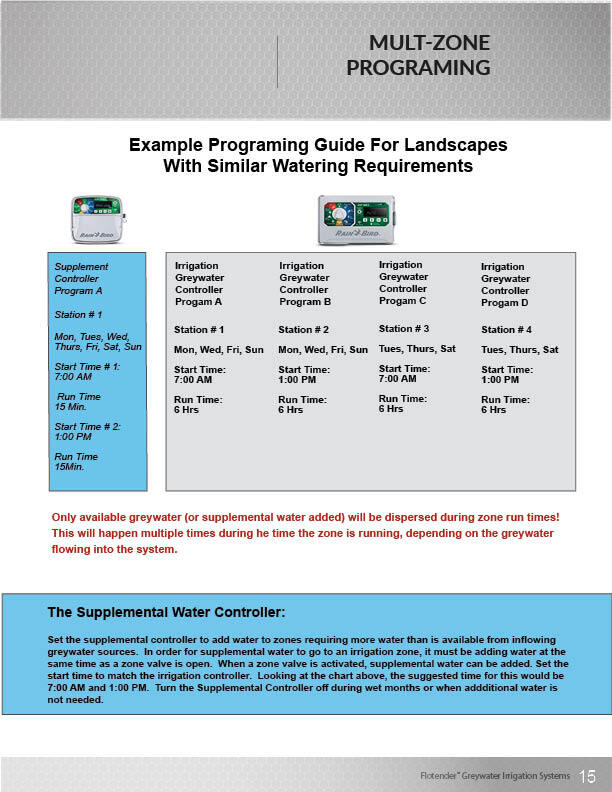

A Multi-Zone greywater system includes electric zone valves and controls to disperse inflowing greywater as received, to selected areas throughout the day.

Both systems can be supplemented with potable greywater with the optional AFS-GL supplemental water packages.

LOCATE THE GREYWATER PROCESSOR:

The first step in the Flotender system installation is to determine the location of the greywater processor. In-flowing greywater must be either gravity-fed from the building’s greywater stub-out or pumped into the greywater processor using an external transfer station.

ABOVE-GROUND GREYWATER PROCESSOR INSTALLATIONS:

Ensure that the greywater processor is placed at an elevation which can be gravity-fed from the stub-out in the building. It is recommended that the processor and external components are placed on a level surface with at least 29” of clearance above the top of the processor’s lid for filter removal.

FOR IN-GROUND GREYWATER PROCESSOR INSTALLATIONS:

For in-ground installations, excavate and place the Greywater Processor on 1 inch of compact sand. Sand will protect the bottom of the processor from sharp objects and help in leveling. Ensure that the incoming greywater is able to gravity-flow from the building stub-out.

LOW GREYWATER STUB-OUTS:

For installations where the greywater stub-out is below the intake of the greywater processor, a lift station may be installed. The lift station features a built-in pump, and activation float switch which pumps the incoming greywater up and into the greywater processor intake port. Once the greywater processor has been placed and the greywater stub-out connected, the expansion reservoirs can be connected.

Overflow:

Overflow from the processor can flow back to the building sewer or to a suitable drain basin or septic system.

Overflow can also flow back to building sewer system.

SECONDARY FILTER AND PERFORMANCE INDICATOR INSTALLATION AND PIPING

After the greywater processor has been installed you will need to install the secondary filter and the piping between the secondary filter, the performance indicators and the greywater processor.

INSTALLING THE GREYWATER DRIP IRRIGATION SYSTEM

Flotender recommends using Netafim Bioline® dripline for the greywater drip irrigation system. The installation process is straightforward using Netafim insert fittings. Consult the Netafim website for additional design and installation questions.